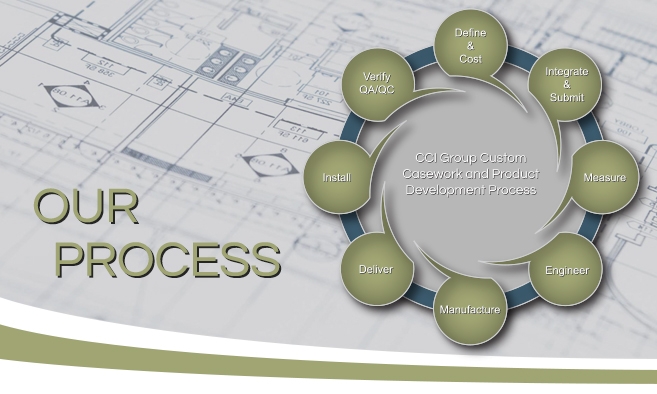

Our Process

Our Process

CCI Group recently transitioned from a batch manufacturing facility to a lean manufacturing facility. The challenging part of this transition involved the adoption of certain principles that were in conflict with the custom manufacturing or ETM (Engineered to Manufacture) process. In essence, CCI Group is a high volume custom casework and fixtures manufacturing company. Our processes have not changed too much—we just have some new terminology to describe how we do business. The following description applies to every product or service that CCI Group offers to the marketplace.

CCI Group recently transitioned from a batch manufacturing facility to a lean manufacturing facility. The challenging part of this transition involved the adoption of certain principles that were in conflict with the custom manufacturing or ETM (Engineered to Manufacture) process. In essence, CCI Group is a high volume custom casework and fixtures manufacturing company. Our processes have not changed too much—we just have some new terminology to describe how we do business. The following description applies to every product or service that CCI Group offers to the marketplace.

Define

For each CCI Group customer, the purpose, focus, objective, and design of the project must be clearly defined, whether it includes casework systems, fixtures or units from our product line. Some CCI customers know exactly what they want and only require verification. Other customers come to CCI looking for innovative solutions. Here, our decades of experience come into play as we become an integral part of the design team. Whatever the objective, our goal is to work with our customer's desires and needs to develop a clear and accurate definition of the outcome for the project.

Integrate and Submit

Integration requires collaboration between CCI Group and our customer. We work together to include the desires and needs of the customer, as well as our adaptations or original designs, into the finished product or project. CCI Group often engages in design team meetings to develop architectural elevations for a casework job or to develop an innovative prototype solution. CCI Group has years of qualified experience to bring to this process. Following the integration process, CCI Group provides the customer with submittals for approval which include material samples and shop drawings of the final design showing elevations, cross sections, and construction details.

Measure

When necessary, measurements of the project are taken on site by CCI Group to verify that our products will meet the contractual requirements outlined by our customer during the Define phase.

Engineer

Make no mistake, our engineering team is a part of the earlier processes, but this is where they make their money. During the Engineering phase, our team takes the submitted items, shop drawings, and the field measurements and produces a clean set of manufacturing documents. These are then reviewed several times prior to release to our production facility.

Manufacture

Once the valid release of manufacturing documents are provided to our production facility, the casework, fixtures, or innovative solutions are manufactured and prepped for shipment. This is a rather involved process that requires the support of the back office staff, the watchful eye of the project manager, and the full weight of our production employees. Our manufacturing facility has redundant production lines, and the ability to produce on-off or re-cuts without interrupting production.

Deliver

Delivery of our product is more than just a truck arriving at a job site or a pallet of products reaching their final destination. We deliver our products and our services. Throughout the preceding phases, an experienced project manager has guided both the customer and their order through each step. This is part of the Deliver phase. The project manager walks the project through the processes until the product reaches the customer. We then deliver our product on-time to the customer’s desired location.

Install

Upon arrival to the job location, CCI Group’s Field Services Group, and field superintendent take over and manage the installation of the product. Installation crews are either sub-contracted locally, dependent on the job site, or we use our own installation team. Installers are provided with CCI Group Installation Manuals which include job specific drawings and floor plans as well as CCI Installation Standards Manual.

Verify

During the installation phase the field superintendent, installation team, and project manager are verifying that the installed products are as agreed to by the customer. This is the final part of the process, but actually takes place during each of the phases. We are continually verifying our outputs.

Quality Assurance and Quality Control

CCI Group’s internal processes incorporate a dynamic QA/QC check system. In an industry where a millimeter can mean the difference between a good product or a rejected product, each phase of our process has a quality control component. At the end of the day we understand that our products are the work areas for doctors and nurses, the vanities for loved ones, the storage for sensitive medical equipment, and the secured location for prescription drugs and medical records. Quality is where we start a project and end with satisfied customers and end users.